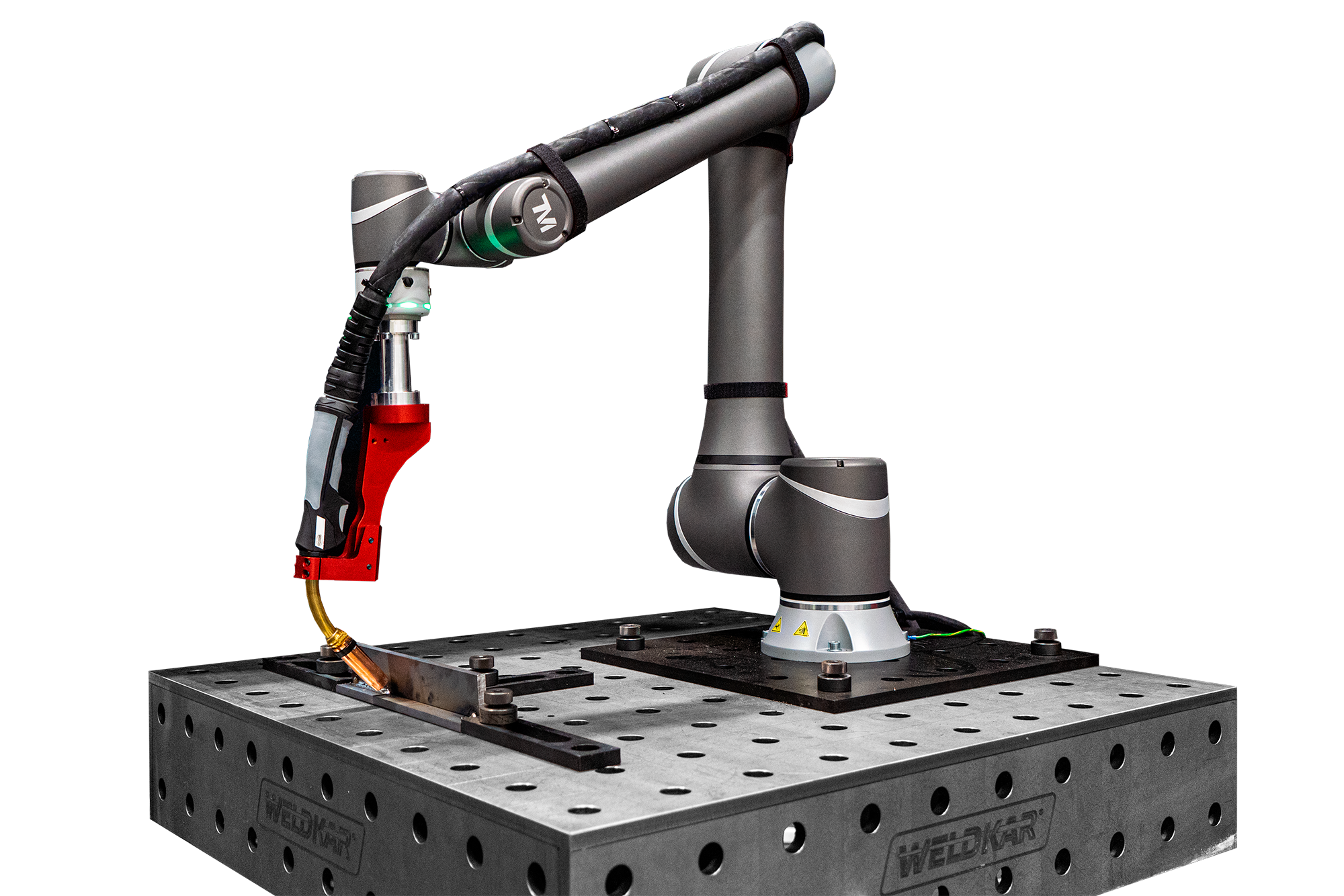

Cobot system WK 12

Cobot system WK 12

Couldn't load pickup availability

With a cobot at their side, the welder no longer needs to worry about repetitive welding. The cobot handles this completely, allowing the welder to focus on specialized welding.

- Suitable for any MIG welding machine

- Works together with the welder

- Easy to program

- Low investment

- No maintenance on the arm

- Mobile and multifunctional

Product description

The 6 axes make it possible to get into any desired position, which also allows rotations to be made.

Universal:

Suitable for any MIG welding machine, thanks to the universal connection.

Simple:

You don't need to be a programmer to use the cobot. You can master the basics in just a few hours.

Safe:

The cobot meets the latest safety requirements for collaborative robots.

Technical specifications : Model WK12 Weight 33.3 kg Max. load capacity 12 kg Max. range 1300 mm Repeatability +/- 0.1 mm Number of degrees of freedom 6 axes

Contact via email info@priorwelding.nl or tel. 0118 674 074

+++++++++++++++++++++++++++++++++++

Convenience serves the welder...

The manufacturing industry is currently experiencing increasing demand for the automation and robotization of highly diverse welding processes while maintaining consistently high quality, especially for smaller batches. This is because automation and robotization can lead to a more efficient production process, resulting in lower costs and faster turnaround times.

In addition to the growing demand for automated welding, it's becoming increasingly difficult for manufacturing companies to find skilled workers. Deploying cobots for repetitive welding can solve this problem, as the cobot handles these tasks, freeing up the welder to focus on more specialized welding. This not only results in a more efficient production process but also in higher work quality.

How does welding with a cobot work?

A cobot, which stands for "collaborative robot," is a robot specifically designed to work seamlessly with humans. This means cobots can collaborate safely and efficiently with human operators in manufacturing, without the need for additional safety measures. This makes cobots an ideal solution for companies looking to automate and improve their production processes while ensuring the safety of their employees. By investing in cobot technology, companies can benefit from increased efficiency, reduced costs, and improved work quality.

Working with a cobot requires an operator. This operator uses easy-to-program software to issue instructions to the cobot, which then follows them. This allows the cobot to support the welding professional in the work process, which can lead to increased productivity and efficiency. Furthermore, cobots can be programmed to perform certain tasks consistently and precisely, which can contribute to higher work quality.

Thanks to the reliability and precision of cobots, it's possible to automate and robotize a wide variety of smaller batch welding operations with consistent quality. When properly configured, cobots can take over batch work from the welder, allowing them to focus on specialized welding. This not only improves the efficiency of the production process but also increases work quality and reduces the risk of human error.

Programming and instructing a cobot is relatively simple and user-friendly. The cobot's six axes allow it to move to any desired position, which also allows for rotation. This offers greater flexibility and allows it to perform a wide range of welding tasks with high precision and consistency. Furthermore, cobots can be quickly switched to different tasks, enabling them to respond to changing production needs and requirements. This increases the flexibility and efficiency of the production process and enables companies to adapt to changing market conditions.

Benefits of cobot welding

- Works together with the welder

- Easy to program

- Low investment costs

- 24-hour production

- Use of current equipment possible

- No maintenance on the arm

- Mobile and multifunctional

Share